Introduction

The individual warfighter now carries more than 100 pounds during combat operations, with a significant amount of that weight attributed to electronic gear and energy needed to power it. [1] In a 2011 memo issued to all U.S. Forces in Afghanistan, General David Petraeus stated, “Energy is the lifeblood of our warfighting capabilities.” [2] Power generation is such an important part of the contemporary warfighter experience that it is key in several initiatives, including Reliance 21, in which energy and power technology is represented as one of 17 communities of research emphasized as part of a larger effort to improve the strategic development of DoD’s science and technology planning.

For land-based warriors, power is required for multiple systems, and reliability is important, especially during missions where maintenance is not possible. [3] Unfortunately, power requirements for sensors, compact communications equipment and light sources have not shrunk as fast as device size and weight. [4] In order to tackle this challenge, alternative forms of energy are proving to be reasonable solutions.

Three existing technologies that warrant reinvestigation are 1) thermo-electrochemical cells, 2) betavoltaic batteries and 3) electromagnetic generators. The processes behind thermo electrochemical cells, betavoltaic batteries and electromagnetic generators have been known since the late 19th and early 20th centuries, but recent advances in science and technology

make them more relevant and practical for uses in military environments.

Devices for Alternative Power Sources

Thermo-electrochemical Cells

Thermo-electrochemical cells, also known as thermogalvanic cells or thermocells, produce electrical power by utilizing electrochemical oxidation-reduction potentials in a temperature-dependent environment to convert thermal energy to electrical energy. [5,6] They have virtually unlimited applications given their simple design, durability and flexibility in form-factor.

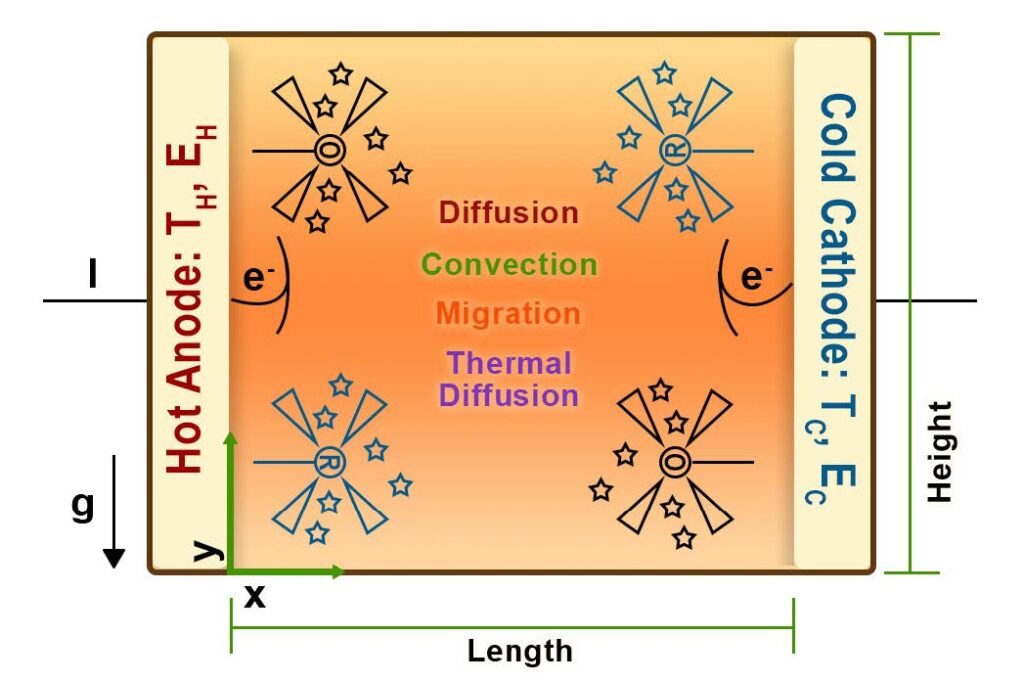

The design of a thermocell is relatively simple (See Figure 1). Electrodes at either end are held at different temperatures. Typically, platinum is used as an electrode material due to its high catalytic activity. [6] Thermocells are filled with a redox electrolyte, which can be an aqueous solution, a non-aqueous solution or a solid-state membrane. [7] Ferri/ferrocyanide is commonly used in order to get high exchange current densities. [6] The movement of electrons between the temperature gradient of the electrodes creates a voltage potential. As long as the temperature difference persists,

a steady state is maintained. [7]

Using flexible materials, such as multi-walled carbon nanotubes, in the electrodes can allow the cells to be molded into a n y s h a p e , which eliminates extra equipment needed to transfer the waste heat to the thermocell. [7] Carbon nanotubes have exceptional electronic, mechanical and chemical properties, which make them ideal for use in many electrochemical applications, particularly due to fast kinetics and a large, accessible internal surface area. [5] Recent research utilizing thermocells with MWCNT electrodes and the traditional ferri/ferrocyanide electrolyte demonstrated an efficiency three times higher than conventional thermocell devices with platinum electrodes. [5] In addition, thermocells using MWCNT electrodes have a relative power conversion efficiency that is 50 percent higher than platinum-based electrode thermocells. [6]

Aside from exploring new electrode materials, the use of ionic liquids, such as ethylammonium nitrate, as electrolytes has been investigated as a replacement for ferri/ ferrocyanide. Thermocells based on ionic liquids can be highly flexible and would allow placement directly onto human skin, taking greater advantage of waste heat produced by the human body to further enhance

the temperature gradient needed to maintain electrical activity from the thermocell.[8]

Betavoltaic Batteries

Betavoltaic batteries, sometimes referred to as betavoltaic cells or just betavoltaics, are a type of nuclear battery that convert the kinetic energy from radioactive decay of a beta-emitting radioisotope into electrical energy through the use of a semiconductor or junction device. [9] The key component in a betavoltaic power source is a beta-emitting material. [10] Beta radiation is essentially a high-energy electron released from an unstable nucleus. Betavoltaic batteries are durable power sources, which can be designed at small sizes because their energy density is 100 to 10,000 times higher than standard chemical batteries where miniaturization is limited by their low energy density. [9,11] Apart from their smaller sizes, betavoltaics can last anywhere from 15 to 100 years and have anti-jamming capabilities, [4,9] making them extremely useful for applications in military equipment and sensor networks that must operate in remote environments such as arctic and mountainous regions. [9,12,13,14] Because of their long lifetime, high energy density and ruggedness, betavoltaics are an excellent option for applications where photovoltaics are not viable power. [9]

The key benefit of a betavoltaic battery is that no re-charging is needed. The battery will continue to operate until the isotope reaches a volume where the radioactive decay becomes impractical to produce enough electrons to power a device or is depleted completely. Although betavoltaics never need to be charged, they will gradually continue to lose power over time as the radioisotope

decays. The lifetime power output and time to failure is directly dependent on the half-life of the radioisotope being used, making the radioisotope the most important component of a betavoltaic battery.

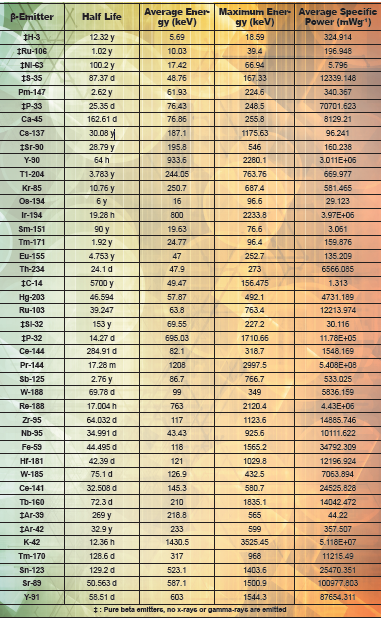

Apart from the half-life, another key consideration is what effect(s) any radiation damage may have on the semiconductor devices. [10] Isotopes with long half-lives are more desirable then isotopes with shorter ones, and isotopes with a single crystal material have been typically preferred to minimize the loss of current. [10] In order to increase power output, radioisotopes with high specific power should be used, [9] and they should have a maximum beta particle energy. [10] A list of beta-emitting isotopes that have been explored for battery use is available in Table 1.

Figure 1: Schematic representation of thermocell. [7] (Released)

Converting the energy from the radioactive decay into electricity is another very important part of betavoltaic, making the semiconducting material just as important as the beta-emitter. The use of silicon combined with radioisotopes has been well-studied since silicon is widely used in integrated circuits and in microelectromechanical systems, is easy to manufacture and has a relatively low cost compared with other semiconductors. [9] Betavoltaics with silicon diodes irradiated with Ni-63 layer show high efficiency. [15] In addition, non-crystalline betavoltaic structures using hydrogenated amorphous silicon have been used. [9] Hydrogenated amorphous silicon has a band gap of 3.3 eV making it an effective candidate for use in betavoltaics. [9]

Table 1: Radioisotopes for betavoltaic batteries. (Addapted from [9] / Released)

Electromagnetic Generators

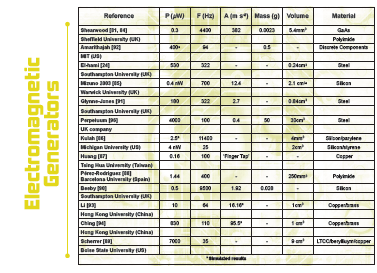

One method for reducing the need for large batteries as power sources has been to convert kinetic energy from motion and vibration into electricity to power wireless sensors and ultra-low power microelectronics devices. [16,17] Harvesting kinetic energy requires a transduction mechanism to convert the energy from movement into electrical energy, [18] and electromagnetic transduction is an effective method for energy scavenging applications. [19,17] A simple design used to produce electromagnetic induction includes the use of permanent magnets, a coil and a resonating cantilever beam, [18] although several variations exist (See Table 2).

Electromagnetic generators employ electromagnetic induction from relative motion between a magnetic flux gradient and a conductor. [18] As the cantilever moves between the magnets, an electromagnetic field evolves leading to the generation of an electrical current. These systems have been used in a range of technologies, including remote sensors, wearable devices and mobile

electronics. [20] While generating electricity through electromagnetic transduction can be a practical and effective means of powering electronic devices, more research is needed especially regarding applications in harsh environments due to inconclusive evidence of the reliability of the device’s moving parts compared with more stationary methods of generating power.

Table 2: Summary of electromagnetic generators. (Adapted from [18] / Released)

Conclusion

The use of betavoltaics, thermocells and electromagnetic generators were initially not feasible since the power demands of devices and systems grew at an exponential rate and the power capacity of these technologies were too small to handle a growth in demand. Ironically, as power demands increase, it may become more practical to explore utilizing these technologies as a means to power small devices and sensors individually rather than continuing to develop methods of powering entire systems. Although these technologies are over 100 years old, a resurgence in their interest for meeting energy demands of high-power networks may prove effective for military applications in rugged and harsh environments.

References

1. Ripley, A. (2015, July 27). “Lightening the Load and Increasing the Self-sustainability of Dismounted Marines.” LinkedIn. Retrieved from, https://www.linkedin.com/pulse/lightening-load-increasing-self-sustainability-marines-anthony-ripley (accessed September 30, 2016).

2. Lynn, B. (2011, June 14). “Energy for the War Fighter: The Department of Defense Operational Energy Strategy.” The White House. Retrieved from, https://www.whitehouse.gov/blog/2011/06/14/energy-war-fighter-department-defense-operational-energy-strategy (accessed September 30, 2016).

3. Kostoff, R., Tshiteya, R., Pfeil, K., & Humenik, J. (2003). Electrochemical power: Military requirements and literature structure. AARMS, 2(1), 5-38. Retrieved from http://www.zmne.hu/aarms/docs/Volume2/Issue1/pdf/01KOST.pdf (accessed October 20, 2016).

4. Litz, M., Russo, J., & Katsis, D. (2016). Tritium-powered radiation sensor network. Proc. SPIE9824, Chemical, Biological, Radiological, Nuclear, and Explosives (CBRNE) Sensing XVII. http://dx.doi.org/10.1117/12.2222177

5. Hu, R., Cola, B. A., Haram, N., Barisci, J. N., Lee, S., Stoughton, S. … Baughman, R. H. (2010). Harvesting Waste Thermal Energy Using a Carbon-Nanotube-Based Thermo-Electrochemical Cell. Nano Letters Nano Lett., 10(3), 838-846. doi:10.1021/nl903267n

6. Qian, W., Cao, M., Xie, F., & Dong, C. (2016). Thermo-Electrochemical Cells Based on Carbon Nanotube Electrodes by Electrophoretic Deposition. Nano-Micro Lett. Nano-Micro Letters, 8(3), 240-246.doi:10.1007/s40820-016-0082-8

7. Salazar, P. F., Kumar, S., & Cola, B. A. (2013). Design and optimization of thermos-eolectrochemical cells. Journal of Applied Electrochemistry, 44(2), 325-336.doi:10.1007/s10800-013-0638-y

8. Uhl, S., Laux, E., Journot, T., Jeandupeux, L., Charmet, J., & Keppner, H. (2014). Development of Flexible Micro-Thermo- electrochemical Generators Based on Ionic Liquids. Journal of Electronic Materials, 43(10), 3758-3764. doi:10.1007/s11664-014-3126-1

9. Alam, T. & Pierson, M. (2016). Principles of Betavoltaic Battery Design. Journal of Energy and Power Sources, 3(1), 11-41. Retrieved from http://www.ethanpublishing.com/uploadfile/

2016/0712/20160712120219845.pdf (accessed October 20, 2016).

10. Olsen, Larry. (1993). Review of Betavoltaic Energy Conversion. Proc. 12th Space Photovolt. Res. Technol. Conf. Retrieved from http://large.stanford.edu/courses/2013/ph241/harrison2/docs/19940006935.pdf (accessed October 20, 2016).

11. Wu, K., Dai, C., & Guo, H. (2011). A theoretical study on silicon betavoltaics using Ni-63. 2011 6th IEEE International Conference on Nano/Micro Engineered and Molecular Systems.

doi:10.1109/nems.2011.6017456

12. Lu, M., Zhang, G., Fu, K., Yu, G., Su, D.,& Hu, J. (2011). Gallium Nitride Schottky betavoltaic nuclear batteries. Energy Conversion and Management, 52(4), 1955-158.doi:10.1016/j.enconman.2010.10.048

13. Wang, G., Hu, R., Wei, H., Zhang, H., Yang, Y., Xiong, X., … Luo, S., (2010). The effect of temperature changes on electrical performance of the betavoltaic cell. Applied Radiation and Isotopes, 68(12), 2214-2217.doi:10.1016/j.apradiso.2010.06.011

14. Mohamadian, M., Feghhi, S.A.H., & Afariadeh, H. (2007). Geometrical Optimization of GaN Betavoltaic Microbatery. Proceedings of the 7th WSEAS International Conference

on Power Systems. Retrieved from http://www.wseas.us/e-library/conferences/ 2007beijing/papers/554-545.pdf (accessed October 20, 2016).

15. Rudenko, K. V., Miakonkih, A. V., Rogojin, A. E., Bogdanov, S. V., Sidorov, V. G., & Zelenkov, P. V. (2016). Planar betavoltaic converter creation with plasma-immersion ion implantation process. IOP Conf. Ser.: Mater. Sci. Eng., 122, 012029. doi:10.1099/1757-899x/122/1/012029

16. Xu, Z., Shan, X., Chen, D., & Xie, T. (2016). A Novel Tunable Multi-Frequency Hybrid Vibration Energy Harvester Using Piezoelectric and Electromagnetic Conversion Mechanisms. Applied Sciences, 6(1), 10. doi:10.3390/app6010010

17. Beeby, S. P., Torah, R. N., Tudor, M. J., Glynne-Jones, P., O’donnell, T., Saha, C.R., & Roy, S. (2007). A micro electromagnetic generator for vibration energy harvesting. Journal of Micromechanics and MIcroengineering, 17(7), 1257-1265. doi:10.1088/0960-1317/17/7/007

18. Beeby, S. P., Tudor, M. J., & White, N. M. (2006). Energy harvesting vibration sources for microsystems applications. Measurement Science and Technology, 17(12). doi:10.1088/0957-0233/17/12/r01

19. Challa, V. R., Prasad, M. G., Shi, Y., & Fisher, F. T. (2008). A vibration energy harvesting device with bidirectional resonance frequency tenability. Smart Materials and Structures, 17(1), 015035. doi:10.1088/0964-1726/17/01/015035

20. Santos, M. P., Ferreira, J. A., Simoes, J. A., Pascoal, R., Torrao, J., Xue, X., & Furlani, E. P. (2016). Magnetic levitation –based electromagnetic energy harvesting: A semi-analytical non-linear model for energy transduction. Sci. Rep., 6, 18579. doi:10.1038/srep1857