Lithium-ion batteries are everywhere, in cell phones, computers, electric vehicles, and even toys, to name only a few places. They have become an integral part of our everyday lives.

Lithium, the element that makes these batteries possible, is considered a critical material by the U. S. Department of Energy because it is essential in many energy applications, creating high demand and the risk of disrupted supplies.

Despite their wide use, it is estimated that only 5% of lithium batteries are currently recycled. Because lithium has high supply risk, discarded batteries are a potential source for recovering lithium. Scientists are developing improved ways to recycle and recover some of that lithium. Typical methods for recycling these batteries require harsh liquid chemicals or heat to complete the process. These processes can produce toxic byproducts and require large amounts of energy.

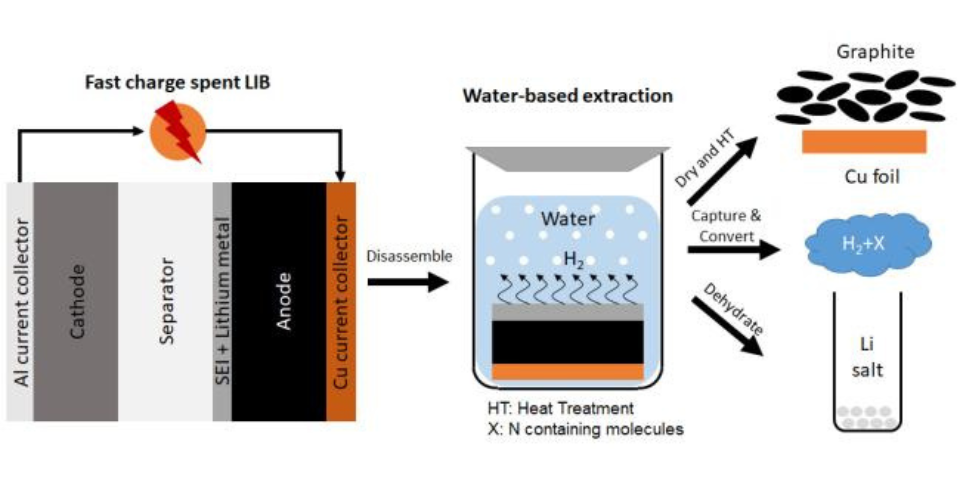

Recently, a team of scientists from the U. S. Department of Energy Ames National Laboratory developed a new recycling process that eliminates the need for chemicals and high heat.