Chemical warfare agents (CWAs) remain a major concern worldwide. This is especially true for nerve agents, which have played a dominant role among CWAs since World War II. There is evidence to suggest that the Islamic State of Iraq and Syria has pursued an aggressive CWA development program in recent years and has likely done so with the help of scientists from a number of countries [1,2]. Consequently, detecting CWAs and providing early warnings have become increasingly important for protecting civilians and military personnel alike.

Currently, CWA detection continues to rely mostly on laboratory-based analytical techniques, such as nuclear magnetic resonance, mass spectrometry, and enzyme-linked immunosorbent assay. These techniques are associated with a number of factors—such as bulky equipment, lengthy sample preparation, solvent management, and wet solutions—that hinder portability and ease of use in the field. Skin- or clothing-based wearable sensors provide excellent portability. However, applications for either wearable sensors and/or wide-area surveillance for CWA detection are typically hard-wired and can come with high installation and maintenance costs, as well as reliability concerns. These factors present the need for wireless sensing.

Our work seeks to wirelessly detect CWA-relevant chemicals from ultra-long distances through the use of robust, flexible, ultra-lightweight, miniature-sized, wearable sensors. These sensors can also be rapidly mass-produced at low cost. Accordingly, we have modified the surfaces of commonly used flexible substrates, such as Kapton polyimide films. Our modifications allow for the greater printability of both water- and organic solvent-based inkjet inks; enhance the robustness and durability of the sensor; and allow for the development of ultra-longrange wireless sensing of CWA-relevant chemicals. This ability enables units in the field to efficiently create an agnostic sensing network on-demand. In addition, the wireless feature provides units the capacity to assess the threat while remaining at a safe distance from potentially harmful agents.

Surface Modification for Enhanced Printability and Robustness

Most commonly-used flexible substrates, such as Kapton polyimide or polyethylene terephthalate films, are highly hydrophobic and relatively inert. These characteristics inhibit the deposition of water-based inks. However, the complete inkjet printing of an entire device often requires the deposition of both water- and organic solvent-based inks onto the same substrate surface.

As an improvement on traditional surface modification methods—such as UV/ ozone treatment [3,4], plasma etching [4,5], ion-beam etching [6,7], acid [4,8], and/or base treatments [9-11], and laser ablation [12-14]—we recently developed several facile, environmentally-friendly, gentle, and inexpensive methods to surface-modify flexible Kapton substrates. These methods have the added benefits of not compromising the structural integrity and properties of the substrates or generating environmentally-harmful byproducts or waste. For example, a computer-automated layer-by-layer (LbL) deposition process was used to apply polyelectrolyte multilayers (PEMs) to flexible and inherently hydrophobic Kapton HN films to tune their surface hydrophobicity [15]. This surface modification enabled a higher degree of printability of both water- and organic solvent-based inkjet inks onto the substrates. To our knowledge, this PEM-based Kapton surface modification method was the first to use only weak polyelectrolytes. Compared to prior work, which used strong polyelectrolytes, our weak-polyelectrolyte method can systematically and easily control the substrate’s properties by varying the pH of the polyelectrolyte solutions [16]. These properties include the thickness and interpenetration of the PEM layers and the wettability of the resulting Kapton surfaces.

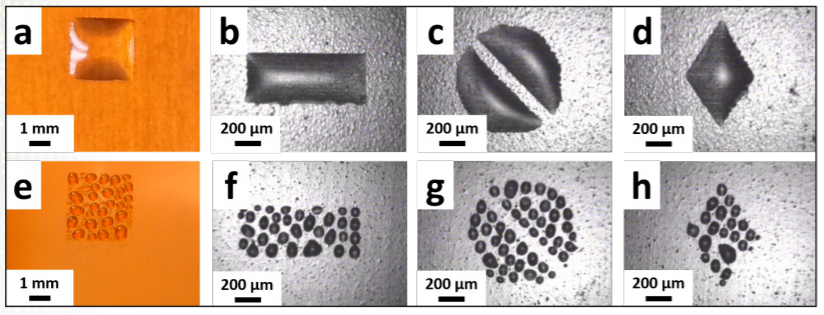

In another instance, we developed a bio-enabled and maximally mild LbL approach to surface-modify Kapton HN substrates [17]. Similar to the aforementioned PEM-based surface modification method, this novel bio-inspired method also significantly reduced the inherent surface hydrophobicity of the substrates, enabling a higher degree of wettability of both water- and organic solvent-based inkjet inks. As shown in Figure 1, multiple precisely-controlled shapes (a square, a rectangle, a circle with a 100 µm-wide gap in the center, and a diamond) were able to be inkjet-printed as designed on surface-modified Kapton substrates (upper panel, Figure 1, a-d). water-based ink drops made isolated small “islands” when printed on surface-unmodified Kapton substrates (lower panel, Figure 1, e-h).

Figure 1: Optical (A and E) [15] (used with permission from the Royal Society of Chemistry) and optical microscopic (B, C, D, F, G and H)

images of various patterns printed surface modified (upper panel) and unmodified (lower panel) Kapton substrates with water-based inkjet

inks [17] (licensed under Creative Commons Attribution 4.0 International License)

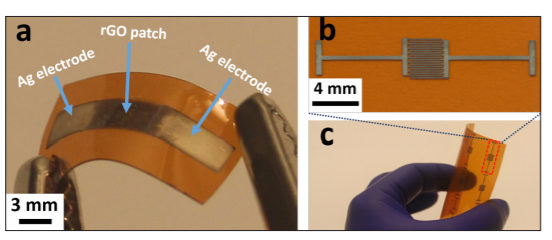

Figure 2: (A) Inkjet-printed flexible, robust, ultra-lightweight, miniature-sized and wearable CWA-relevant sensors. (B) A reduced graphene oxide-based sensor on surface modified Kapton substrate. (C) Single-walled carbon nanotube-based sensors on surface functionalized Kapton substrate [17,18] (licensed under Creative Commons Attribution 4.0 International License)

Wired Sensing of CWA-relevant Chemicals

Our inkjet-printed flexible sensors have sensed, in a wired fashion, simulants of different types of CWAs. For nerve agent-relevant sensing, we have sensed a number of simulants such as dimethyl methylphosphonate (DMMP), diethyl ethylphosphonate (DEEP), diethyl methylphosphonate, and pinacolyl methylphosphonate. In one example, a proof-of-concept sensor was inkjet-printed with a graphene oxide ink, and the inherent properties of reduced graphene oxide were used to sense DEEP [15]. In another example, a hexafluoroisopropanol group-containing chemoselective compound (selector), which has been shown to interact with the aforementioned organophosphate-based simulants via hydrogen bonding [19, 20], was used to functionalize our sensing materials for enhanced sensitivity and selectivity. A small and structurally simple compound (containing only one hexafluoroisopropanol group per molecule), 2-(2-hydroxy-1, 1, 1, 3, 3, 3-hexafluoropropyl)-1-naphthol, was employed as our selector to sense DMMP [17] and DEEP [18]. Based on the assumption that more target molecules absorbed to a sensor will result in greater measurable changes, we used a bifunctional polymer comprising multiple hexafluoroisopropanol groups and a naphthalene group in our nerve agent-relevant sensors. This bifunctional compound binded to both our sensing materials (semiconducting single-walled carbon nanotubes) via π-π interaction (which facilitated its uniform and thin deposition on the sensing materials) and our target vapor via hydrogen bonding interactions.

So far, our inkjet-printed flexible, ultra-lightweight, and miniature-sized chemiresistive sensors have detected the aforementioned nerve agent simulants at a parts-per-billion (ppb) level. We are also developing efficient ways to enhance the sensitivity of our inkjet-printed sensors. We developed a facile, mild, and generic wet chemical approach to modify the material and geometry of the inkjet-printed interdigitated electrodes of our semiconducting carbon nanotube-based sensors. As a result, the sensitivity to DEEP was enhanced by at least five times [18]. This work suggests that the electrode material and the Schottky contacts between the semiconducting sensing elements and electrodes might play an important role in the gas sensing process. This finding can be applied on a generic scientific basis to other semiconducting material-based sensors for sensitivity enhancement.

Aside from nerve agent-relevant sensing, we have also sensed simulants of other types of CWAs. Methyl salicylate, which is a simulant of the blister agent mustard gas, has been one of our sensing targets. We have utilized different techniques to screen for the correct selectors for this compound. In one instance, we screened selectors based on Hansen solubility parameters [21], and, as a result, some commercially available, low-cost polymers such as poly(ethylene-co-vinyl acetate) were used to functionalize our inkjet-printed sensors. In another example, we screened selectors for this simulant based on its interactions with biological molecules. Salicylic acid-binding protein 2, which exhibits strong esterase activity and high and specific binding affinity for this compound [22], was chosen as a selector. We have detected methyl salicylate vapor at ppb levels and are developing various ways to further enhance the sensitivity.

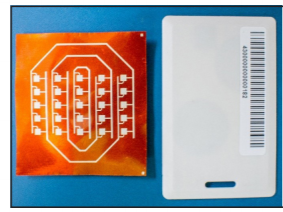

Fully-inkjet-printed Chipless RFID Cross-polarizing Van Atta Sticker

The Van Atta sticker, pictured in Figure 3, follows a sensing, chipless RFID approach that allows for a reading range more than one order of magnitude higher than the previous state of the art. Chipless RFIDs are electromagnetic circuits and structures able to encode data or translate environmental properties into a remotely-detectable electromagnetic signature. The main advantage of chipless RFIDs is their lack of requirement for active components—as their name indicates—and therefore an ability to operate independent of a power source. Consequently, most such designs can also be fully-printed onto flexible substrates to produce ultra-low-cost stickers. Nevertheless, their linear behavior has traditionally made their detection and interrogation quite challenging at ranges in excess of 1 m.

Figure 3 (Left): Optical image picture of the

fully-inkjet-printed chipless Van Atta tag

next to a standard-size credit card [23]

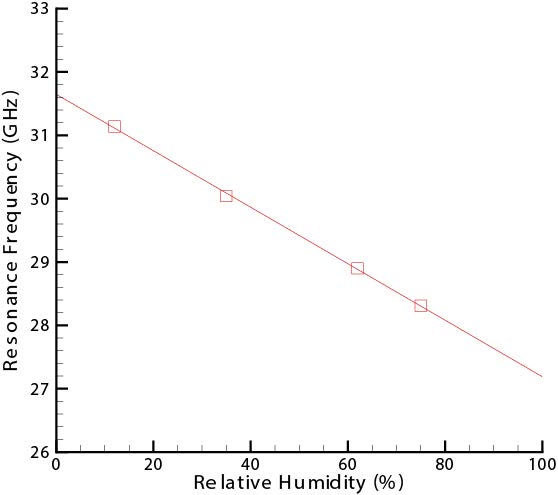

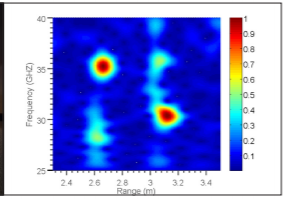

As a preliminary demonstration of this tag’s utility, the device was printed onto a polyimide film (Kapton) that has a humidity-sensitive dielectric permittivity, which creates a detuning of the resonant frequency of the device and can directly be associated with a given humidity level (shown in Figure 4). Coupled with a high-performance matched-window spectrogram data-processing approach, this structure was localizable at a range in excess of 30m (shown in Figure 5), and is compatible with high-density implementations. In such a context, it has the ability to discriminate among different tags in both frequency and range dimensions (shown in Figure 6). Using a high-performance reader, a reading range on the order of 50 m was reported for a similar structure [24].

Figure 4 (Right): Measured variations of the tag resonant frequency relative to the ambient relative humidity level [23]

Figure 5 (Left): Configuration used for the

30 m-range interrogation of the chipless tag/sensor [26]

Figure 6 (Right): Measured spectrogram of

a multi-sensor/tag configuration [26]

Semi-passive Kilometer-range-compatible Energy-autonomous Millimeter-wave RFID

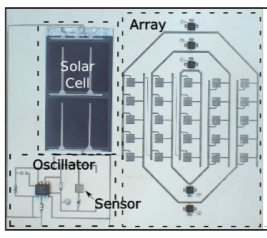

This RFID device is based on a millimeter-wave Van Atta reflect array semi-passive backscatter front-end, for real-time gas monitoring at kilometer-range. Its operational frequency was set at 28 GHz in what is to become one of the future 5G mobile bands. This device can operate using power levels of low two-digit microwatts—three to four orders of magnitude lower than that of the standard active communications technologies used in Internet of Things devices—and can therefore operate autonomously, exclusively on harvested ambient energy. Switches were used to turn the tag “on” and “off,” thereby modulating its radar-cross-section and introducing detectable non-linearities in the response received by the reader. In the sensing tag, the switches are cycled at the sensing-dependent oscillation frequency of a 555 timer.

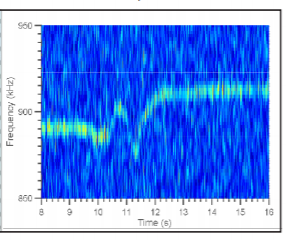

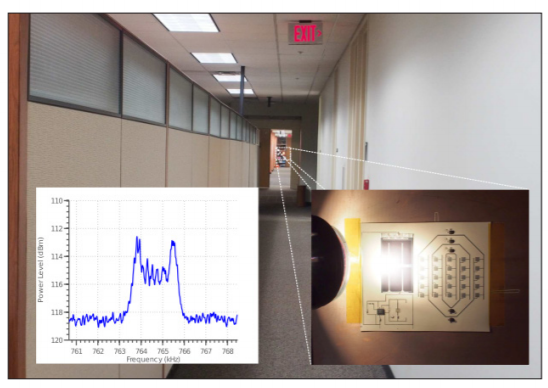

One of the most valuable attributes of this approach is its ability to seamlessly integrate inkjet-printed resistometric sensors. Indeed, the oscillation frequency is determined by an RC constant where, in this scenario, the printed sensor constitutes the gas-dependent resistive element. The system, shown in Figure 7, was inkjet-printed onto a flexible piece of seven millimeter-thick Rogers ULTRALAM 3850 liquid crystal polymer substrate, where the lumped components, timer, flexible amorphous silicon solar cell, array, switches, and inkjet-printed CNT-PABS ammonia sensor were integrated into a thin and flexible energy-autonomous sticker. The RFID was interrogated by sending a 28 GHz continuous wave (CW) towards the tag, before using this CW to down-convert the received signal. A real-time spectrogram of the signal obtained during an ammonia sensing event is shown in Figure 8. This test demonstrates the ability to carry out real-time gas detection using the tag in an energy-autonomous fashion. The tag was also interrogated at a range of 80 m indoors in the configuration shown on Figure 9. Further improvements in timer stability will extend this range to distances on the order of a kilometer.

Figure 7 (Left): Picture of the printed semi-passive Van Atta tag [27

Figure 8 (Right): Measured real-time spectrogram of the tag during an ammonia detection event [27]

Figure 9: Configuration used for the 80 m range interrogation of the semi-passive tag/ sensor [27]

Summary

Aiming at wirelessly sensing CWA-relevant chemicals from ultra-long distances, we have produced inkjet-printed, robust, flexible, ultra-lightweight, miniature-sized, wearable sensors and utilized these sensors to detect simulants of different types of CWAs (i.e., nerve and blister agents) at ppb levels. RFID-based ultra-longrange wireless sensing platforms, which are capable of integrating any single or set of resistometric or capacitive printed sensors, have been developed and tested as proof-of-concept. Efforts are underway to integrate our CWA-relevant sensors to wireless sensing platforms. The low cost and portability of sticker-based detection may significantly contribute to protecting the warfighter at home and abroad. Taken as a whole, these advances in flexible substrate modification techniques, chipless RFID sensing stickers, and energy-autonomous tags represent a significant step towards the provision of using lightweight, flexible stickers for detecting CWAs

References

1. Ingham, J., & Reynolds, M. (2015, November 20). Now jihadis want to GAS us: ISIS savages are plotting CHEMICAL WEAPONS attack on UK. Express. Retrieved from https://www.express.co.uk/news/uk/620801/ ISIS-chemical-attack-UK-nerve-gas-intelligence- officials-believe

2. Sims, A. (2015, November 20). Isis ‘aggressively pursuing development of chemical weapons’, say Iraqi and US officials. Independent. Retrieved from http://www.independent.co.uk/news/world/middle-east/isis-aggressively-pursuing-

development-of-chemical-weapons-say-iraqi-and-us-officials-a6742576.html

3. Le, T. R., Lakafosis, V., Lin, Z. Y., Wong, C. P., & Tentzeris, M. M. (2012). Inkjet-printed graphene-based wireless gas sensor modules. Paper presented at the 2012 IEEE 62nd Electronic Components and Technology Conference (ECTC), San Diego, CA, USA.

4. Gouzman, I., Girshevitz, O., Grossman, E., Eliaz, N., & Sukenik, C. N. (2010). Thin film oxide barrier layers: Protection of Kapton from space environment by liquid phase deposition of titanium oxide. ACS Applied Materials & Interfaces, 2(7), 1835-1843. doi:10.1021/am100113t

5. Inagaki, N., Tasaka, S., & Hibi, K. (1992). Surface modification of Kapton film by plasma treatments. Journal of Polymer Science Part A-Polymer Chemistry, 30(7), 1425- 1431. doi:10.1002/pola.1992.080300722

6. Bachman, B. J., & Vasile, M. J. (1989). Ion-bombardment of polyimide films. Journal of Vacuum Science & Technology A-Vacuum Surfaces and Films, 7(4), 2709-2716. doi:10.1116/1.575779

7. Shin, J. W., Jeun, J. P., & Kang, P. H. (2010). Surface modification and characterization of N+ ion implantation on polyimide film. Macromolecular Research, 18(3), 227-232. doi:10.1007/s13233-010-0310-x

8. Ghosh, I., Konar, J., & Bhowmick, A. K. (1997). Surface properties of chemically modified polyimide films. Journal of Adhesion Science and Technology, 11(6), 877- 893. doi:10.1163/156856197×00967

9. Huang, X. D., Bhangale, S. M., Moran, P. M., Yakovlev, N. L., & Pan, J. S. (2003). Surface modification studies of Kapton (R) HN polyimide films. Polymer International, 52(7), 1064-1069. doi:10.1002/pi.1143

10. Thomas, R. R., Buchwalter, S. L., Buchwalter, L. P., & Chao, T. H. (1992). Organic- chemistry on a polyimide surface. Macromolecules, 25(18), 4559-4568. doi:10.1021/ma00044a016

11. Park, Y. J., Yu, D. M., Ahn, J. H., Choi, J. H., & Hong, Y. T. (2012). Surface modification of polyimide films by an ethylenediamine treatment for a flexible copper clad laminate. Macromolecular Research, 20(2), 168-173. doi:10.1007/s13233-012-0025-2

12. Least, B. T., & Willis, D. A. (2013). Modification of polyimide wetting properties by laser ablated conical microstructures. Applied Surface Science, 273, 1-11. doi:10.1016/j. apsusc.2012.12.141

13. Gallais, L., Bergeret, E., Wang, B., Guerin, M., & Benevent, E. (2014). Ultrafast laser ablation of metal films on flexible substrates. Applied Physics A-Materials Science & Processing, 115(1), 177-188. doi:10.1007/s00339-013-7901-2

14. Guo, X. D., Dai, Y., Gong, M., Qu, Y. G., & Helseth, L. E. (2015). Changes in wetting and contact charge transfer by femtosecond laser-ablation of polyimide. Applied Surface Science, 349, 952-956. doi:10.1016/j.apsusc. 2015.05.089

15. Fang, Y. N., Hester, J. G. D., deGlee, B., Tuan, C. C., Brooke, P. D., Le, T. R., . . .Sandhage, K. H. (2016). A novel, facile, layer-by-layer substrate surface modification for the fabrication of all-inkjet-printed flexible electronic devices on Kapton. Journal of Materials Chemistry, 4(29), 7052-7060. doi:10.1039/c6tc01066k

16. Yoo, D., Shiratori, S. S., & Rubner, M. F. (1998). Controlling bilayer composition and surface wettability of sequentially adsorbed multilayers of weak polyelectrolytes. Macromolecules,

31(13), 4309-4318. doi:10.1021/ ma9800360

17. Fang, Yunnan, Hester, Jimmy G. D., Su, Wenjing, Chow, Justin H., Sitaraman, Suresh K., & Tentzeris, Manos M. (2016). A bio-enabled maximally mild layer-by-layer Kapton surface modification approach for the fabrication of all-inkjet-printed flexible electronic devices. Scientific Reports, 6, 39909. doi:10.1038/srep39909

18. Fang, Y. N., Akbari, M., Sydanheimo, L., Ukkonen, L., & Tentzeris, M. M. (2017). Sensitivity enhancement of flexible gas sensors via conversion of inkjet-printed silver electrodes into porous gold counterparts. Scientific Reports, 7. doi:10.1038/s41598-017-09174-5

19. Snow, E. S., Perkins, F. K., Houser, E. J., Badescu, S. C., & Reinecke, T. L. (2005). Chemical detection with a single-walled carbon nanotube capacitor. Science, 307(5717), 1942-1945. doi:10.1126/science. 1109128

20. Mirica, K. A., Azzarelli, J. M., Weis, J. G., Schnorr, J. M., & Swager, T. M. (2013). Rapid prototyping of carbon-based chemiresistive gas sensors on paper. Proceedings of the National Academy of Sciences of the United States of America, 110(35), E3265-E3270. oi:10.1073/pnas.1307251110

21. Hansen, C. M. (2000). Hansen Solubility Parameters: a User’s Handbook. New York: CRC Press.

22. Forouhar, F., Yang, Y., Kumar, D., Chen, Y., Fridman, E., Park, S. W., . . . Tong, L. (2005). Structural and biochemical studies identify tobacco SABP2 as a methyl salicylate esterase and implicate it in plant innate immunity. Proceedings of the National Academy of Sciences of the United States of America, 102(5), 1773-1778. doi:10.1073/ pnas.0409227102

23. Hester, J. G. D., & Tentzeris, M. M. (2016). Inkjet-printed Van-Atta reflectarray sensors: A new paradigm for long-range chipless low cost ubiquitous Smart Skin sensors of the Internet of Things. In 2016 IEEE Mtt-S International Microwave Symposium.

24. Dominique, H., Hester, J. G. D., Aubert, H., Pons, P., & Tentzeris, M. M. (2017). Long range wireless interrogation of passive humidity sensors using Van-Atta cross-polarization effect and 3D beam scanning analysis. Paper presented at the Microwave Symposium (IMS), 2017 IEEE MTT-S International.

25. Wang, Y., Du, X. S., Li, Y., Long, Y., Qiu, D., Tai, H. L., . . . Jiang, Y. D. (2013). A Simple Route to Functionalize Siloxane Polymers for DMMP Sensing. Journal of Applied Polymer Science, 130(6), 4516-4520. doi:10.1002/app.39724

26. Hester, J. G. D., & Tentzeris, M. M. (2016). Inkjet-printed flexible mm-wave van-atta reflectarrays: A solution for ultralong-range dense multitag and multisensing chipless RFID implementations for IoT smart skins. IEEE Transactions on Microwave Theory and Techniques, 64(12), 4763-4773. doi:10.1109/tmtt.2016.2623790

27. Hester, J. G. D., & Tentzeris, M. M. (2017). A Mm-wave ultra-long-range energy-autonomous printed RFID-enabled van-atta wireless sensor: At the crossroads of 5G and IoT. Paper presented at the Microwave Symposium (IMS), 2017 IEEE MTT-S International.